Cumi Ignition Electrodes

Price 1 INR/ Unit

Cumi Ignition Electrodes Specification

- Condition

- New

- Type

- Others

- Size

- INCH

- Usage

- Industrial

- Height

- INCH Inch (in)

- Product Type

- IGNITION ELECTRODES FOR BOILER IGNITION

- Structure

- Others

- Weight

- GRAMS Grams (g)

- Pressure

- Others

- Color

- N/A

- Style

- LIGHT PINK WITH SMOOTH FINISHING

- Material

- N/A

- Width

- MILLIMETER Millimeter (mm)

- Length

- INCH Inch (in)

Cumi Ignition Electrodes Trade Information

- Minimum Order Quantity

- 1 , , Unit

- FOB Port

- VISAKHAPATNAM

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Day

- Delivery Time

- 1 Hours

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- SAFE AND QUALITY PACKING IN THERMACOOL CHAMBERS.

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 2015

About Cumi Ignition Electrodes

"Cumi Ignition Electrode" are in ready stock with saptam corporation. Saptam corporation is supplier of synthetic thermic fluid oil, all types of oil/gas burners & boiler, burner spares like sequence controllers, ignition transformer, photocells, ignition electrodes, fuel pumps, nozzles, blower fans, diffuser plates, solenoid valves, burner motor, temperature sensors and temperature controllers etc.

BOILER IGNITION ELECTRODES,Ignition Electrode, Ignition Rods, Boiler Ignition Rods, Ignition Rod Assembly, Electrode Assembly, Boiler Electrodes, BoilerIgnition Electrode, CUMI Ignition Electrode.

DUNGS multiblock, burner motor, ecoflam burner spares, Riello burner spares, burner blast tube, monarch nozzle, Danfoss nozzle, ignition electrodes, diffuser plates, Berganzo nozzle, oil controller, gas controller, Thermic fluid pump & SPARES, BPRV, IPRV, SUNTEC A2L75CK.

Reliable Ignition Solution

Cumi Ignition Electrodes are crafted for durability and consistent performance within industrial boilers and burners. Their robust build quality and smooth finish ensure efficient ignition, reducing downtime and maintenance concerns. Sourced from trusted Indian distributors, manufacturers, and suppliers, they meet rigorous industry standards.

Tailored to Industrial Needs

These electrodes come in a range of sizes with accurate inch and millimeter specifications, allowing for seamless integration into various industrial systems. Their versatility makes them suitable for a wide range of burner and boiler configurations, providing flexibility to engineers and maintenance teams.

FAQs of Cumi Ignition Electrodes:

Q: How do I install Cumi Ignition Electrodes in an industrial boiler or burner?

A: Installation involves securing the electrode in the designated mount within the boiler or burner following the systems specifications for size (inches for height and length, millimeters for width). Ensure all safety measures are observed during installation.Q: What are the main benefits of using Cumi Ignition Electrodes?

A: Cumi Ignition Electrodes offer reliable ignition performance, a smooth surface for steady sparking, and long-lasting durability, reducing maintenance frequency. Their compatibility with a wide range of industrial systems is a key advantage.Q: When should ignition electrodes be replaced in industrial applications?

A: It is recommended to inspect electrodes periodically for wear or residue buildup. Replace them if the spark weakens, ignition fails repeatedly, or according to the maintenance schedule advised in your equipment manual.Q: Where are Cumi Ignition Electrodes available for purchase in India?

A: These electrodes can be sourced from authorized distributors, retailers, wholesalers, suppliers, and traders throughout India. Check with your preferred industrial equipment provider for availability.Q: What is the process for selecting the right Cumi Ignition Electrode size?

A: Determine the exact dimensions required for your boiler or burner using the provided specifications (height and length in inches, width in millimeters). Consult with a supplier to match your systems needs for a proper fit.Q: How can Cumi Ignition Electrodes improve industrial burner operations?

A: They provide swift and dependable ignition, minimizing system downtime and enhancing operational safety. Their robust manufacture ensures prolonged service life, contributing to efficient and cost-effective plant maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ignition Electrodes And Ionisation Electrodes Category

H Type Ignition Electrodes

Price 1 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Others

Usage : Industrial

Material : N/A

Product Type : ELECTRODES FOR BOILER AND BURNER IGNITION

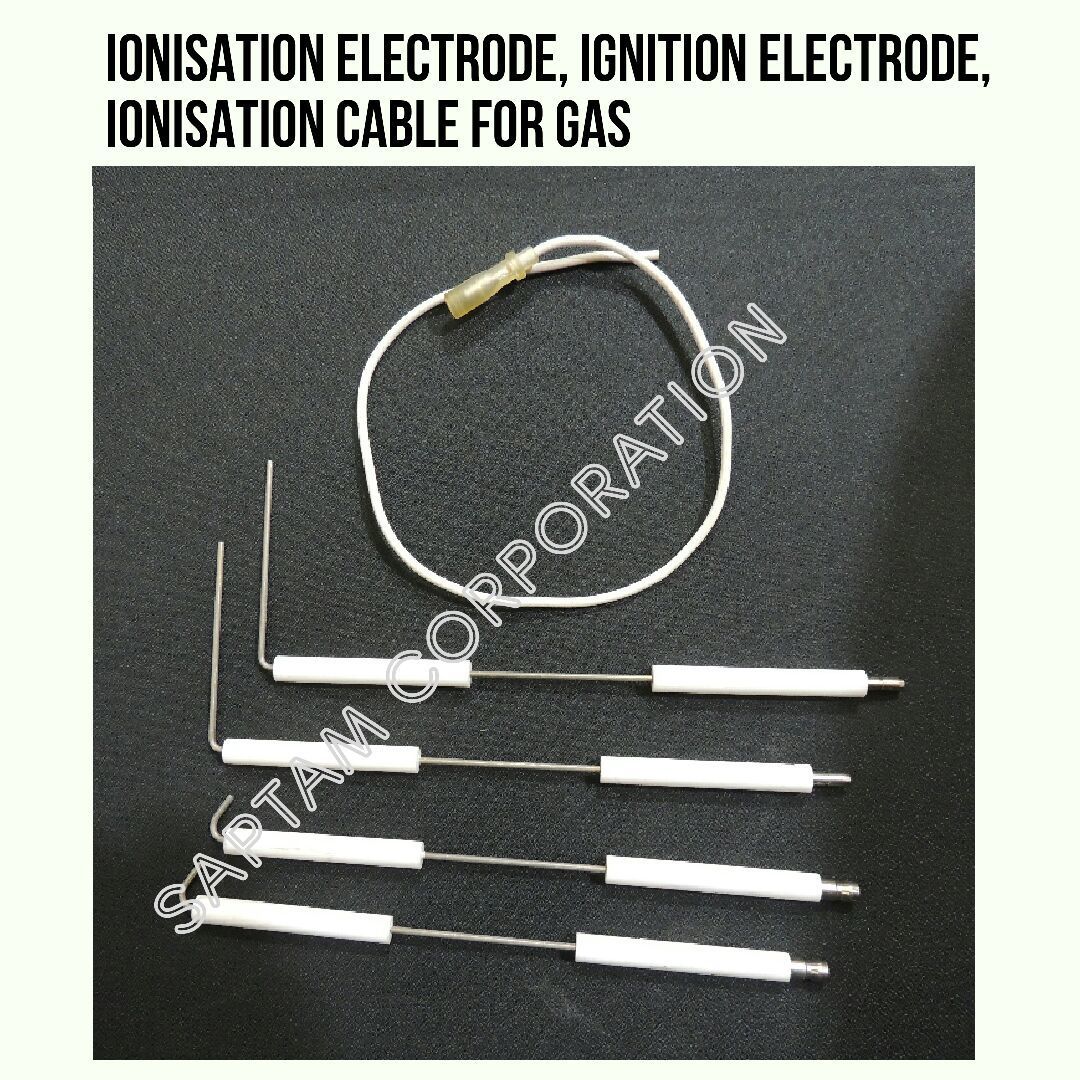

IONISATION ELECTRODE,IGNITION ELECTRODE,IONISATION CABLE FOR GAS

Price 1 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Others

Usage : Industrial

Material : N/A

Product Type : IONISATION ELECTRODE,IGNITION ELECTRODE,IONISATION CABLE

Bentone Burner Electrode

Price 1 INR / Unit

Minimum Order Quantity : 1 Millimeter

Structure : Others

Usage : Industrial

Material : N/A

Product Type : BENTONE BURNER ELECTRODE

H Type Electrodes

Price 600 INR

Minimum Order Quantity : 100 Units

Structure : Others

Usage : BOILER AND BURNERS

Material : N/A

Product Type : H TYPE ELECTRODES

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry