Call: 08045804562

Two Stage Burners

Price 60000 INR/ Piece

MOQ : 1 Piece

Two Stage Burners Specification

- Style

- Horizontal Mount

- Life Span

- 10+ years

- Temperature

- 40C - 200C

- Heat Efficiency

- Up to 96%

- Pressure

- 2-4 bar

- Condition

- New

- Voltage

- 220V / 380V

- Fuel Type

- Diesel / Natural Gas / LPG

- Fuel Consumption

- 3-45 kg/hr (depending on model)

- Capacity

- 50000-1400000 kcal/hr

- Output

- Consistent two-stage flame modulation

- Material

- Cast Iron & Stainless Steel

- Part Type

- Industrial Burner

- Dimension (L*W*H)

- 850 mm x 550 mm x 430 mm

- Function

- Provides staged firing for improved efficiency and combustion

- Flame Safeguard

- Integrated UV Sensor

- Control Panel

- Digital Microprocessor Based

- Serviceability

- Quick Serviceable Design

- Ignition System

- Automatic Electric Ignition

- Ambient Operating Conditions

- -10°C to +45°C

- Burner Head Type

- Multi-nozzle Stainless Steel

- Installation Type

- Easy Plug-in Design

- Application Area

- Steam Boiler, Hot Water Boiler, Furnace, Oven, Industrial Heating

- Noise Level

- Below 78 dB(A)

- Air/Fuel Ratio

- Standard Adjustable

About Two Stage Burners

Experience the Elite choice in industrial heating with our Two Stage Burners-on Sale now! Order Today to enhance your system with first-class efficiency and splendiferous reliability. Featuring a superb automatic electric ignition, digital microprocessor-based control panel, and an integrated UV flame safeguard, these burners deliver outstanding safety and performance. The multi-nozzle stainless steel head and adjustable air/fuel ratio guarantee up to 96% heat efficiency with whisper-quiet operation under 78 dB(A). Designed for easy plug-in installation and quick serviceability, this unit is perfect for steam boilers, furnaces, and ovens. Robust construction promises a lifespan of over 10 years.

Versatile Two Stage Burners for Industrial Applications

Engineered for industrial excellence, our Two Stage Burners are superb for a wide range of uses-be it steam boilers, hot water boilers, furnaces, or ovens. These burners are splendiferously suitable for factories, processing plants, and institutional facilities that require reliable, high-capacity performance. Designed for first-class combustion and efficiency, they cater to intensive heating demands in both large and small-scale industrial environments.

Flexible Payment Terms and Trusted Supply Standards

We offer flexible payment options, including advance payments and bank transfers. Share your requirements for an immediate Quotation-our Stock Ready supply ensures swift dispatch and prompt Handover. As an elite supplier, our burners are manufactured to meet stringent international and local certifications, assuring you of first-class safety and compliance for every order. Streamlined processes and reliable supply ability optimize your procurement experience.

Versatile Two Stage Burners for Industrial Applications

Engineered for industrial excellence, our Two Stage Burners are superb for a wide range of uses-be it steam boilers, hot water boilers, furnaces, or ovens. These burners are splendiferously suitable for factories, processing plants, and institutional facilities that require reliable, high-capacity performance. Designed for first-class combustion and efficiency, they cater to intensive heating demands in both large and small-scale industrial environments.

Flexible Payment Terms and Trusted Supply Standards

We offer flexible payment options, including advance payments and bank transfers. Share your requirements for an immediate Quotation-our Stock Ready supply ensures swift dispatch and prompt Handover. As an elite supplier, our burners are manufactured to meet stringent international and local certifications, assuring you of first-class safety and compliance for every order. Streamlined processes and reliable supply ability optimize your procurement experience.

FAQ's of Two Stage Burners:

Q: How does the automatic electric ignition system enhance the performance of these burners?

A: The automatic electric ignition system ensures quick, reliable start-ups and improves operational safety by reducing manual intervention. This results in smoother, more efficient burner operation and minimizes downtime.Q: What are the main benefits of the two-stage firing feature?

A: Two-stage firing optimizes combustion, boosts heat efficiency up to 96%, and allows for adjustable power output based on demand. This leads to improved fuel economy and reduced emissions, making the burners both cost-effective and eco-friendly.Q: When should the burners be serviced to maintain optimal performance?

A: Thanks to the quick serviceable design, we recommend routine inspections every 6-12 months, depending on usage intensity. Regular maintenance ensures peak performance and helps extend the burner's lifespan beyond ten years.Q: Where can these burners be installed?

A: These burners are suitable for steam boilers, hot water boilers, furnaces, ovens, and various industrial heating applications, making them ideal for factories, processing plants, and large institutional setups.Q: What certifications support the quality of these burners?

A: Our two-stage burners are engineered to comply with both local and international safety and quality certifications, ensuring every unit meets rigorous standards for reliability, efficiency, and operational safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Burner Spares And Boiler Spares Category

Gas Burner Spares

Price 1 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : VOLTS Volt (v)

Condition : New

Color : N/A

Usage : INDUSTRIAL BURNERS

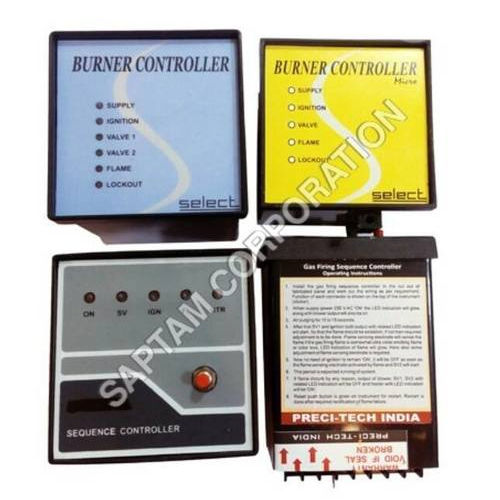

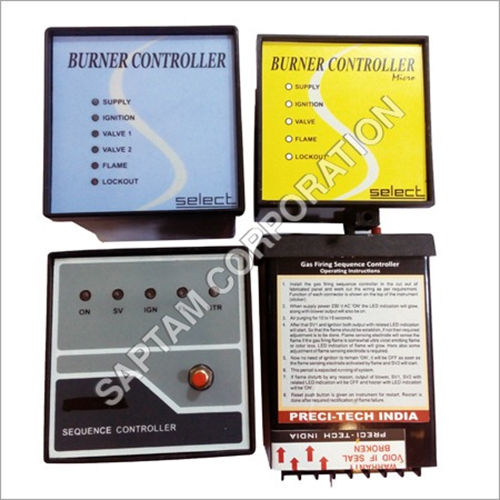

Burner Controller

Price 1 INR / Unit

Minimum Order Quantity : 1 Ampere

Voltage : VOLTS Volt (v)

Condition : New

Color : MULTICOLOUR

Usage : BURNER SEQUENCE CONTROLLING

Burner Programmer Controller

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : VOLTS Volt (v)

Condition : New

Color : MULTICOLOUR

Usage : INDUSTRIAL HEATING ELEMENTS

Simens Burner Sequence Controller

Price 25000 INR / Piece

Minimum Order Quantity : 50 Pieces

Voltage : 220240 Volt (v)

Condition : New

Color : Black

Usage : Simens Burner Sequence Controller

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry